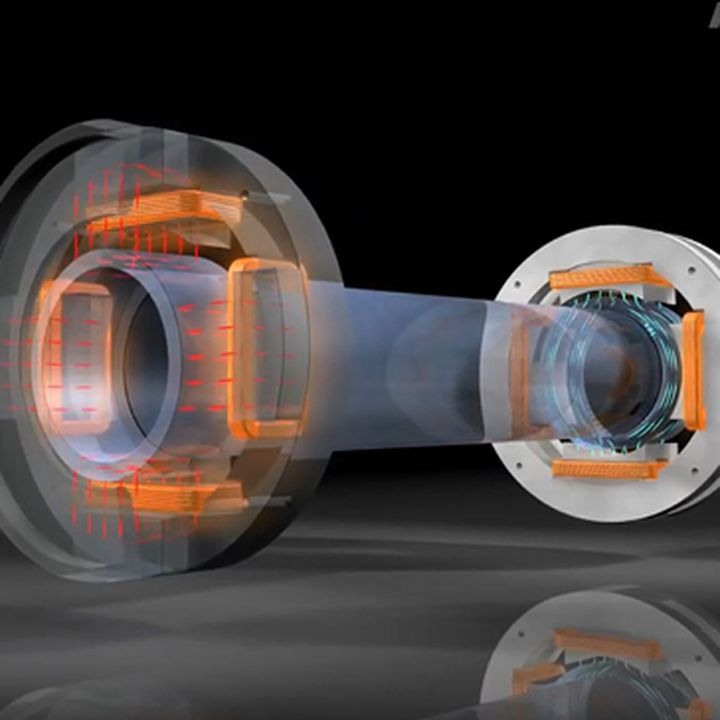

Applications of LeviSpin

Application examples for our drill spindle

6D technology is a popular choice for applications where standard drilling technology reaches its limits, for example in the machining of difficult-to-machine materials such as titanium or ceramic, when shorter processing times are needed, when the surface quality needs improving, for deep-hole drilling or when highly accurate process data is needed.

Aerospace

6D drilling is idea for realizing rivet drill holes for aerospace applications. The drilling process stays cooler, and productivity and drill hole quality are significantly improved while drill bit wear is significantly reduced. Drill holes are drilled using MQL or dry drilling and with backward deburring if needed. Layer thicknesses and layer transitions are detected, and quality-relevant piece-specific process data is generated.

Deep-hole drilling

6D technology produces chips that dissipate the process heat almost as quickly as it is generated. This keeps the workpiece cooler, and the drill will run out less than with conventional drilling. In addition, the spindle shaft can be tilted for the targeted compensation of the drill run-out. This achieves dramatic improvements of productivity and drill hole quality.

Difficult-to-machine materials

The benefits of 6D technology become apparent precisely where conventional drilling reaches its limits. Significantly lower process temperatures increase the material removal rate by a factor of 2–4, and drill bit wear is reduced at least by half. The spindle sensors provide highly accurate process data, and the 6D technology guarantees controlled quality.

소재지

Edge

Chrome

Safari

Firefox