KePlast for blow molding machines

Comprehensive hardware & software portfolio enhanced by the blow molding process expertise

Complete automation solutions

We speak the language of the industry

Thanks to 40 years of experience in controlling various kinds of plastic processing machines, the experts from KEBA have acquired extensive plastics industry and technology knowledge. As a result, we can respond to your requests in all areas quickly and competently and discuss issues with you on an equal footing in the specialist language that you are accustomed to.

All-in-one solution for any blow molding machine needs

The KePlast portfolio is characterized by scalable hardware and a common software platform that enables maximum flexibility for all business requirements. By flexibly adding your know-how to our existing blow molding-specific hardware and software solution, maximum differentiation and short time to market guarantee your competitive advantage. This can cover a wide range of blow molding machine types, from hydraulic to all-electric and from standard machines to complex production cells.

Your Benefits:

- Scalable range of powerful compact and modular controllers, I/Os, servo drives & motors

- Wide range of intuitive HMI panels with or without hardware keyboard, single- or multitouch operation

- Future-proof & state-of-the-art Linux platform

- Modular KePlast Application Framework with many blow molding process-specific functions and libraries

- Parison control up to 400 set points

- Accurate closed loop temperature control

- Drive based energy-saving concepts

- Innovative closed-loop control technologies

- Condition monitoring possibilities

- Industry 4.0 readiness through smart communication interfaces such as OPC UA and EUROMAP protocolls

Everything you need to know in one video

Christop Hauser, KePlast Technical Sales Manager, summarizes all the necessary information.

Video Chapters:

Which hardware does the KePlast blow molding portfolio cover?

What hardware does the typical KePlast blow molding solution consist of?

What software does the KePlast blow molding solution use?

How to operate the HMIs with KeViewStyle Multitouch?

What functionality does the KePlast blow molding application offer?

Hardware Portfolio

KEBA provides a comprehensive range of hardware, including HMI, controls, I/Os, drives, and motors, to cover the needs of any blow molding machine.

Large stationary multi-touch panels of the KeTop series ensure high-quality and comfortable operation, supported by software features like gesture control (taping, swiping, drag & drop, back-to-home-screen gesture), favorite masks, split screens, customizable menus, and dashboards.

Additionally there is the possibility to extend the machine by optional mobile hand held terminals. For complex machines, the innovative KEBA safe wireless KeTop allows cable less operation around the whole machine.

The customers can select between cost-optimized solutions with IOs integrated on the CPU or highly flexible IO configurations with a modular CPU and IO architecture. With EtherCAT as our standard field bus, the KEBA KeConnect C5 IOs can be installed in decentralized stations distributed in the machine.

The drive system KeDrive D3 is a modular common DC bus drive system. It offers a wide power range and allows innovative concepts to optimize the energy consumption of the machine like active power supplies, passive capacitor modules, active energy storage,...

KeTop HMIs

Stationary & mobile operating devices for an intuitive & user-friendly operation

Progressive, user-friendly stationary and mobile operating panels are the market leaders in terms of usability. Designed together with the globally based machine operators, the HMI selection covers a wide range of single- and multitouch 7"-18" passive panels, cutting-edge gesture-operated Linux-based active panels up to 21", and unique KeTop Mobile series with 7" and "10" handheld devices.

KeTop stationary active & passive panels

- Real-time control of machines

- Single- or multitouch

- Available in different sizes - 7", 12", 15", 18" & 21"

- Haptic feedback

- Customizing of hard- und software

- Optimized price-performance ratio

KeTop mobile & wireless panels

The mobile operation for your needs

- Ergonomic design

- High security

- Ruggedness suitable for industrial use

- Tailormade

KeControl

Controls for all who expect more from an automation system

Intel x86-based single to quad-core KeControl C5 CPUs with future-proof Linux-based software architectures ensure the full control of your machine processes. Choose from the flexibly expandible CP 5xx line or the compact industry-optimized CP 0xx line.

KeControl C1 // Industry-optimized controller with built-in I/O elements

- Optimized end-to-end solution with a compact design for optimal performance

- Integrated functions such as control & visualization on a single computer

- Best value for money thanks to centralized I/Os

- Robust housing and excellent ease of servicing

- 256MB - 4GB RAM

- Innovative closed-loop control concepts

KeControl C5 // A new dimension of flexible expandability

- Compact but high-performance design

- Easy individualization and expandability

- Scalable

- Freedom of design through top connectivity

KeConnect

I/Os with an ideal ratio between function and size

The hardware portfolio also includes high-end KeConnect C5 I/O modules, which can be connected directly to the control or via bus coupling in a decentralized location.

- Different I/O sizes to choose from

- Attached to C5 controller or remote via bus coupler

- Connection to external control via EtherCat

- Tailored to your needs

KeDrive D3

Compact multi-axis drive system with integrated safety technology

Our scalable offering of energy-efficient servo drives provides maximal performance while keeping electricity costs to a minimum. In addition, use a drive-based condition monitoring feature to realize predictive maintenance solutions and increase the productivity of your machine.

- 75 % more compact design with KeDrive D3

- Safe motion in the axis controller

- Easy installation

- High dynamics

- Single, double & triple axes for multiple possible combinations

KeDrive DMS2

compact and high-performance synchronous servo motors

KeDrive DMS2 motor portfolio is characterized by:

- Best reliability

- High overload capability

- Low torque ripple

- One cable for power and encoder signal

The software makes the difference

The KePlast Software is a future-proof framework, based on an open and modern software architecture, fully customizable for any customer requirements. Alongside the essential features like User Management, Unit Switching, Alarm & Value Change History, Backup & Restore, and Help Framework there are many blow molding-specific functions and libraries, featured next with their main benefits.

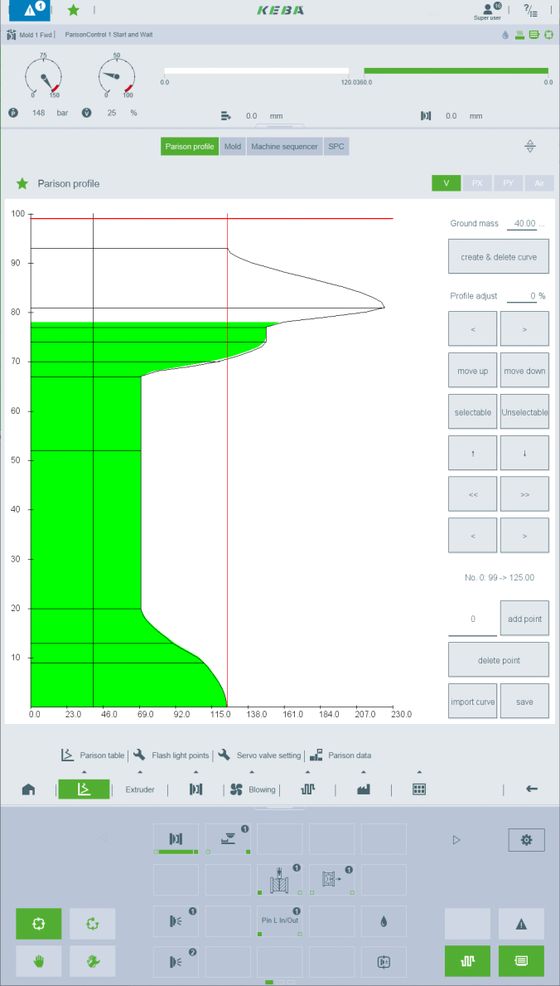

KePlast Parison Control

- Wall thickness control library and HMI screen

- Up to 400 points

- Save and load multiple parison profiles

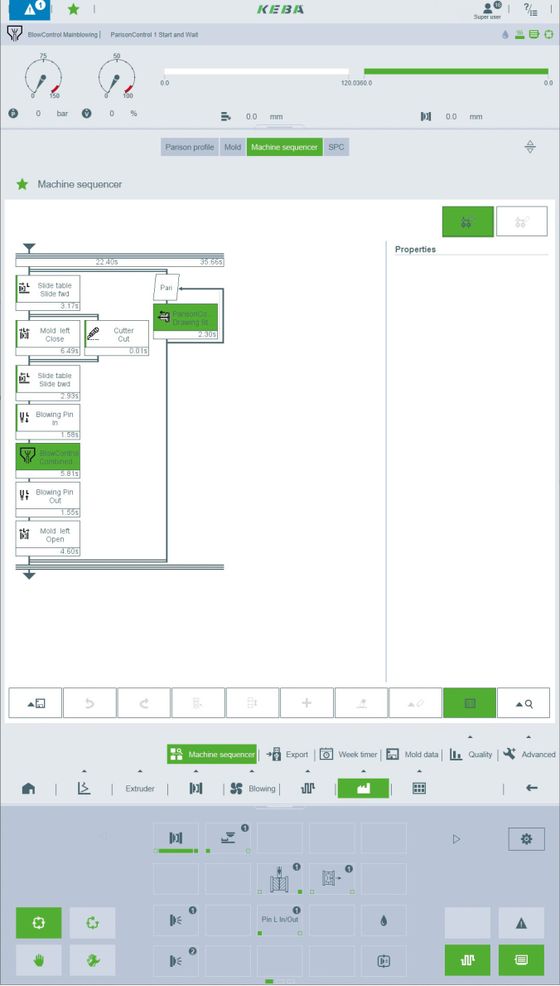

KePlast MachineSequencer

- Intuitive onscreen editor for editing the machine sequence

- Flexible building blocks: Loops, conditions, subsequences,...

- Monitoring of movement status and times

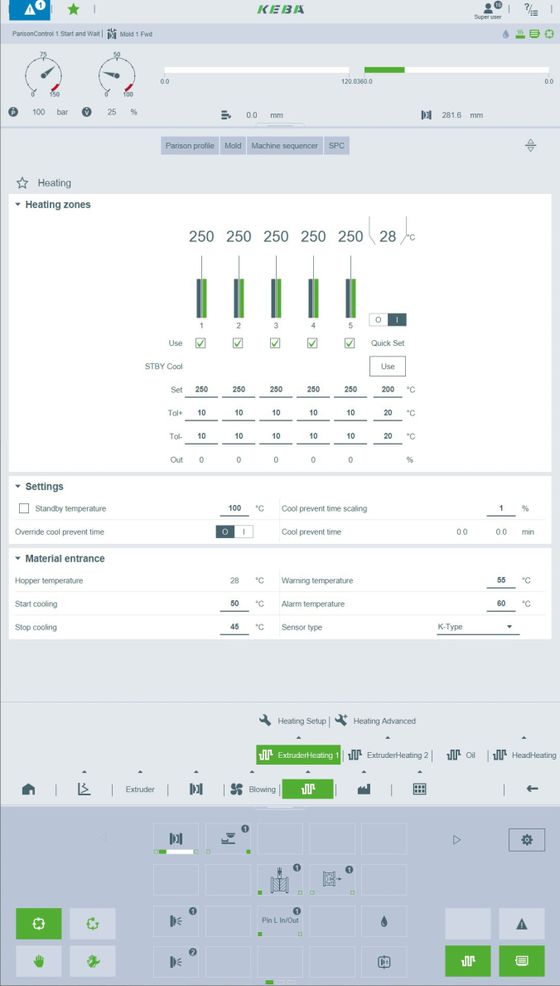

KePlast Extruder Heating // Temperature Control

- Accurate closed-loop temperature control algorithms

- Heating & cooling

- Automatic PID tuning

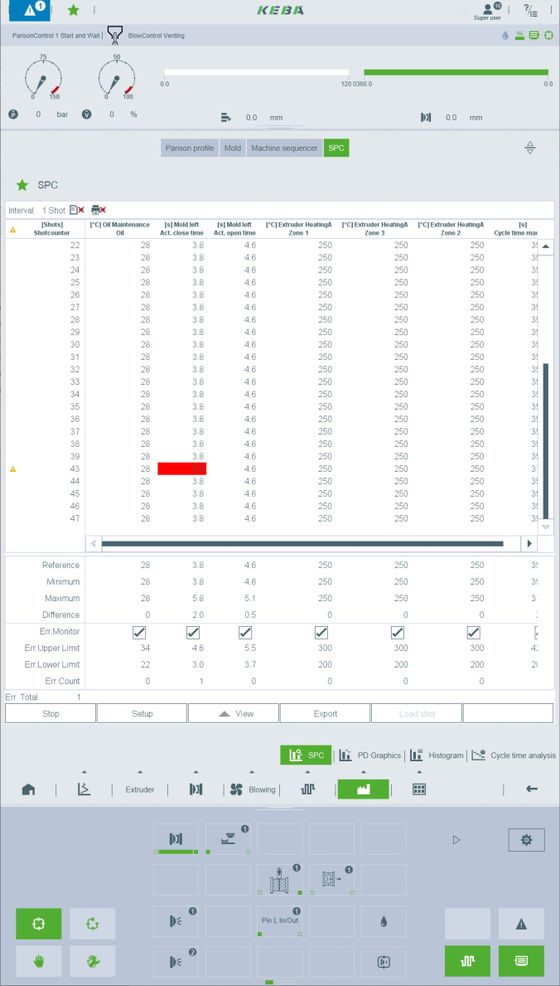

KePlast SPC // Shot Quality Control

- All quality criteria under control

- Monitor critical process parameter

- Flexible selection of relevant parameter

- Configuration of warning limits & error reaction

- Export function for saving production data externally

Frequently asked questions

Downloads

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.