This is not only a control room.

It is also your clever simulation.

Visit us at this year's WindEnergy and find out how we can use our experience to help you maximize your savings potential.

At our control room, we will show you how we understand simulation and how it can help you to optimize the load on your turbine and thus save costs. Experience live how intelligent software can protect the material in the wind turbine before and during the feathering run and extend the service life.

We not only offer you pitch solutions with maximum safety, but also intelligent yaw systems and digital services.

Last but not least we would like to present our approach of PitchOne for offshore applications.

You will find us in hall B6 on booth 262.

We will be happy to provide you with a free ticket and reserve time for you to visit our booth.

Our trade fair highlights at a glance!

Load Management

- Final Position Mode

- Safety feathering run with multiple profiles

- Continued operation through sensorless movement

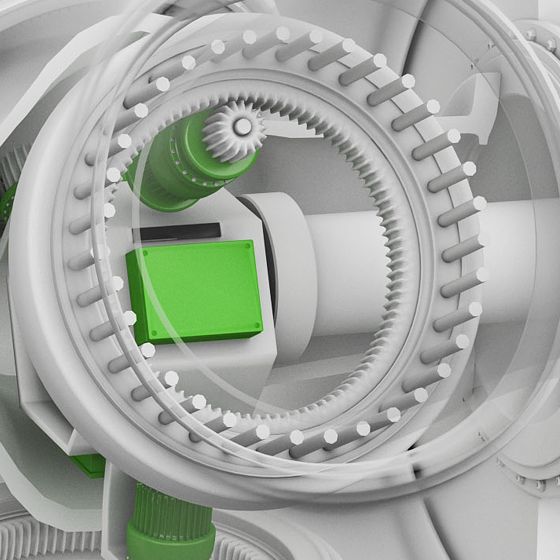

PitchOne Size 3

- For Offshore up to 20 MW Size 3

- Integrated wind specific functions enable compact system design at turbine level

- TÜV certified pitch system with Performance Level E for Safety Run

- Fast backup energy charging via bidirectional DC/DC converter

Pitch and Yaw drive systems for wind turbines

High-performing drive solutions in all operation states

Pitch drive systems

Compact and dedicated Pitch solutions in the 5th product generation

The demand for lowering the levelized cost of electricity (LCoE) in the wind energy sector calls for cost-efficient, robust drive solutions and decentralized approaches to further increase the availability and safety of wind energy. KEBA offers many years of experience and a variety of references around electromechanical Pitch control systems for onshore and offshore wind turbine installations.

We assist you with designing your system and help you find a cutting-edge, cost-optimized solution.

Yaw drive systems

Conventional concepts with motors running directly on the grid involve certain technological drawbacks. Unwanted loads due to abrupt start-up operations increase mechanical wear and tear. In addition, the electrical and hydraulic systems need to harmonize.

These problems can be addressed through the use of a controlled multi-axis drive system that synchronizes and optimizes the drive output power of the individual motors. KEBA’s modular KeDrive D3 system supports this approach using state-of-the-art servo drive technology.

KEBA at VDMA Sustainability Hour

Frank Stege

Head of Product Center Pitch Drives at KEBA,

will speak about the topic of:

"Pushing sustainability in certification through systematic safety in pitch systems"

on September 27, 10:30 am on Energy Transition Stage, hall B6

Venue & Opening Hours

Hamburg Messe und Congress GmbH

Messeplatz 1

20357 Hamburg / Deutschland

KEBA: Hall B6 | Booth 262

Opening hours

September, 24-27, 2024

Tuesday to Thursday: 10:00 - 18:00 | Friday: 10:00 - 16:00

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Business Areas

Newsroom

Edge

Chrome

Safari

Firefox