Safe flights and weather predictions with KEBA technology

- References / Success Stories

- Drive Technology

- 5.3.2025

- Reading Time: {{readingTime}} min

Contents

LEONARDO Germany GmbH is a fully owned subsidiary of Leonardo (Italy), the global high-tech giant and one of the ten biggest companies in the world in the field of aerospace, defense and security.

The business activities of Leonardo’s team in Germany focus on meteorology and domestic security. In addition, the company headquartered in Neuss supports Leonardo’s worldwide business activities in aerospace, defense and security. Around the globe, the group employs more than 49,000 people.

Applications of Weather Radar Systems

Most of the end customers who use Leonardo’s weather radar systems are national weather services, but airports and the military count among them, too. These systems are used for more than just general weather forecasts; for example, in the Caribbean they help calculate the trajectories of hurricanes. Based on this information, decisions can be made about necessary safety measures and whether evacuations of certain regions are required. In areas with a lot of snowfall, these systems help with quick decisions about necessary road closures.

Leonardo also offers a mobile system that can be used for quick predictions of local weather conditions. This can help, for example, in Formula 1 races where data from the measuring station is used to decide whether different tires need to be put on the race cars (if weather conditions are changing). Another useful application is in underground mining, where extreme weather conditions demand quick decisions about the timely evacuation of workers from mines. Likewise, institutions and universities have used parts of such a Leonardo system to track space debris or volcanic ash. In other words, the system can be used to detect particle volumes in general, not specifically rain, snow, or hail.

Longstanding Collaboration Between LEONARDO and KEBA

LEONARDO and KEBA have been collaborating for about 15 years. Christoph Duncker, Product Engineer at LEONARDO Germany GmbH, explains: “Back then, we sourced our drives from a different manufacturer. When learned that one of their products was being discontinued without a clear successor, we started looking for a new partner.” The requirement for a new supplier were high – and KEBA emerged as the winner.

Duncker elaborates: “We chose KEBA Industrial Automation for four reasons. First, KEBA has been involved in pitch and yaw systems for wind turbines for many years. This experience with automation and drive solutions for applications exposed to extreme weather conditions is very applicable to our systems. That was crucial for us.”

For many other components in our system, we simply wanted to remain flexible. For this reason, we needed to find a platform that is not only open and supports the integration of components made by a broad range of suppliers – it also needs to come with the necessary flexibility that allows us to develop our own solutions together with our customers.

Another advantage was KEBA’s open platform. Duncker continues: “We knew exactly what we needed, which allowed us to pick exactly the right KEBA products in terms of requirements and functionality. For many other components in our system, we simply wanted to remain flexible. For this reason, we needed to find a platform that is not only open and supports the integration of components made by a broad range of suppliers – it also needs to come with the necessary flexibility that allows us to develop our own solutions together with our customers. In this respect, we benefit from the comprehensive software libraries built directly into KEBA’sdrive controllers, such as cam modules and the easy synchronization of axes. KEBA’s Kemro X system provides us with exactly this type of flexibility – the open platform is a real asset.”

Technical Requirements for Drive Technology

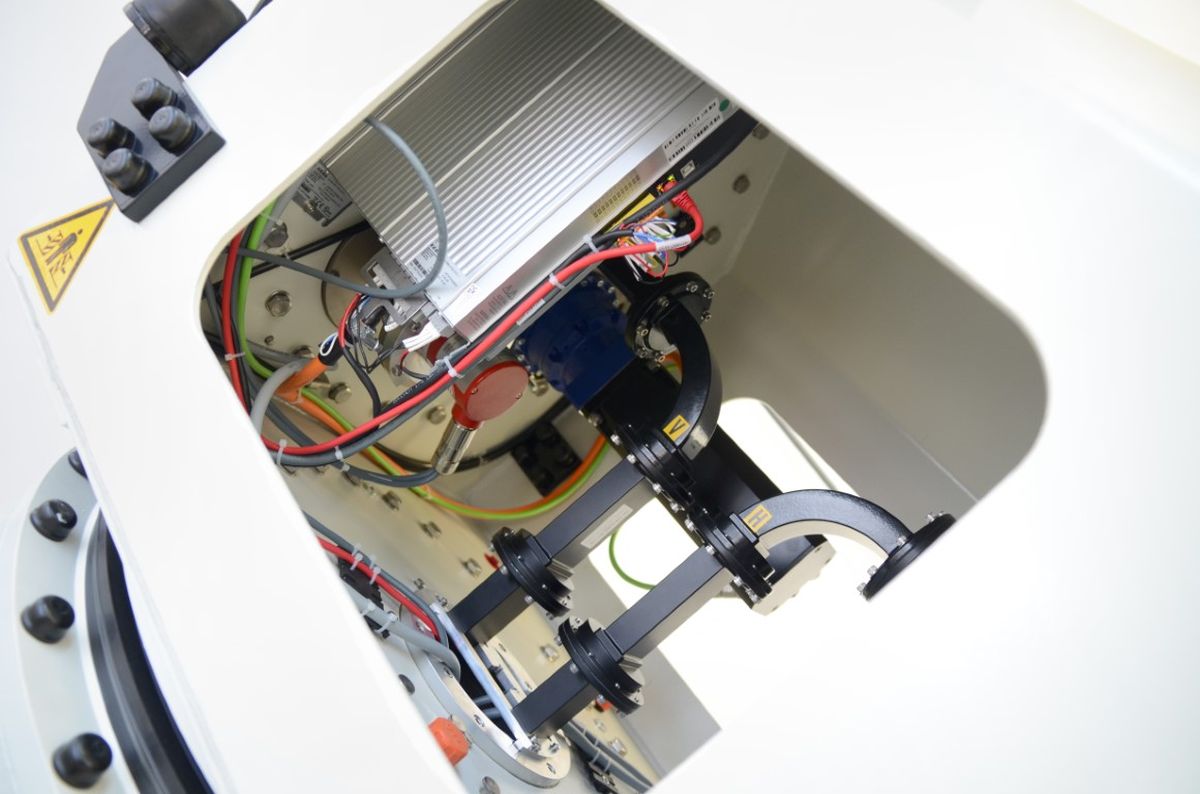

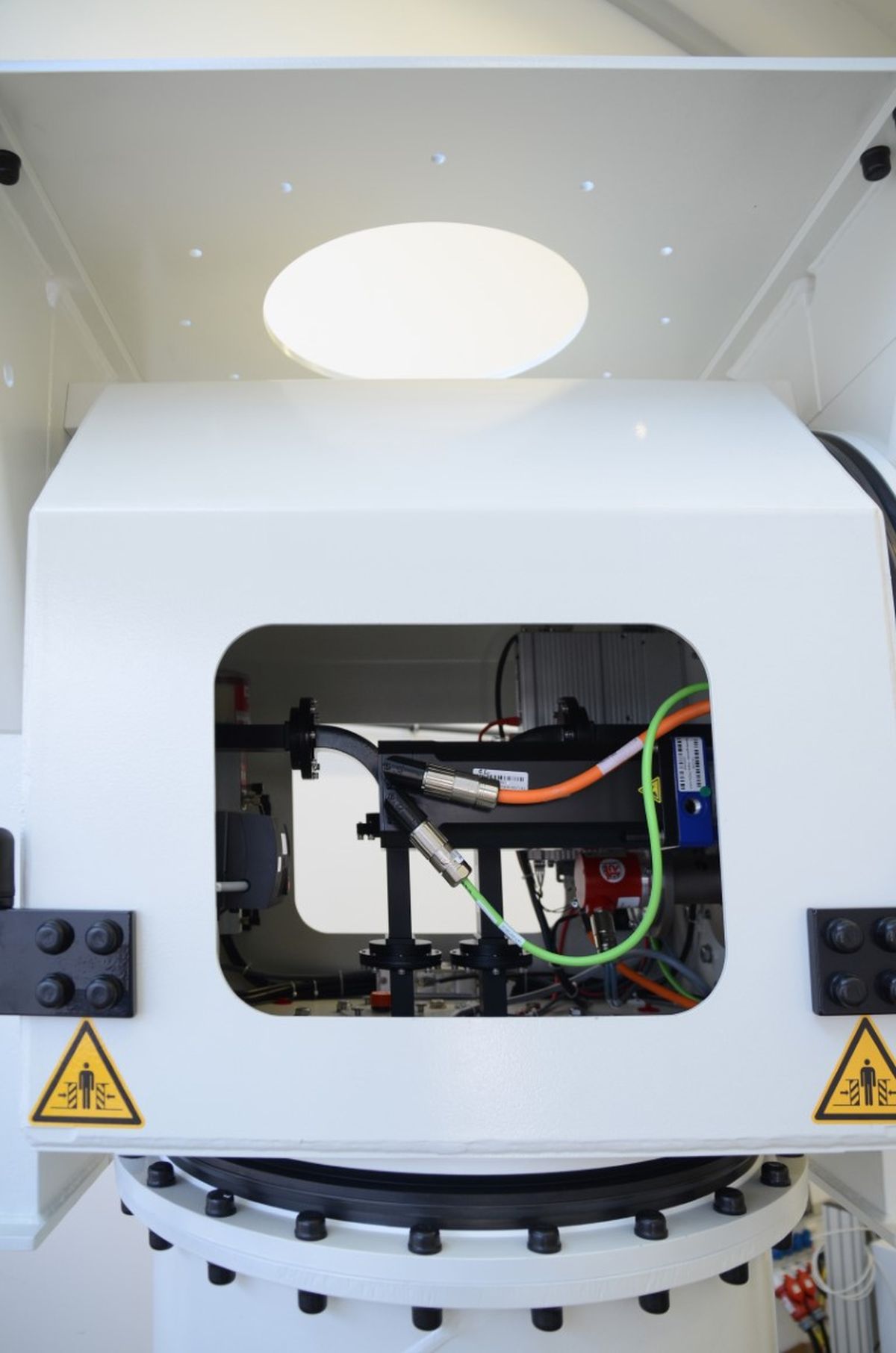

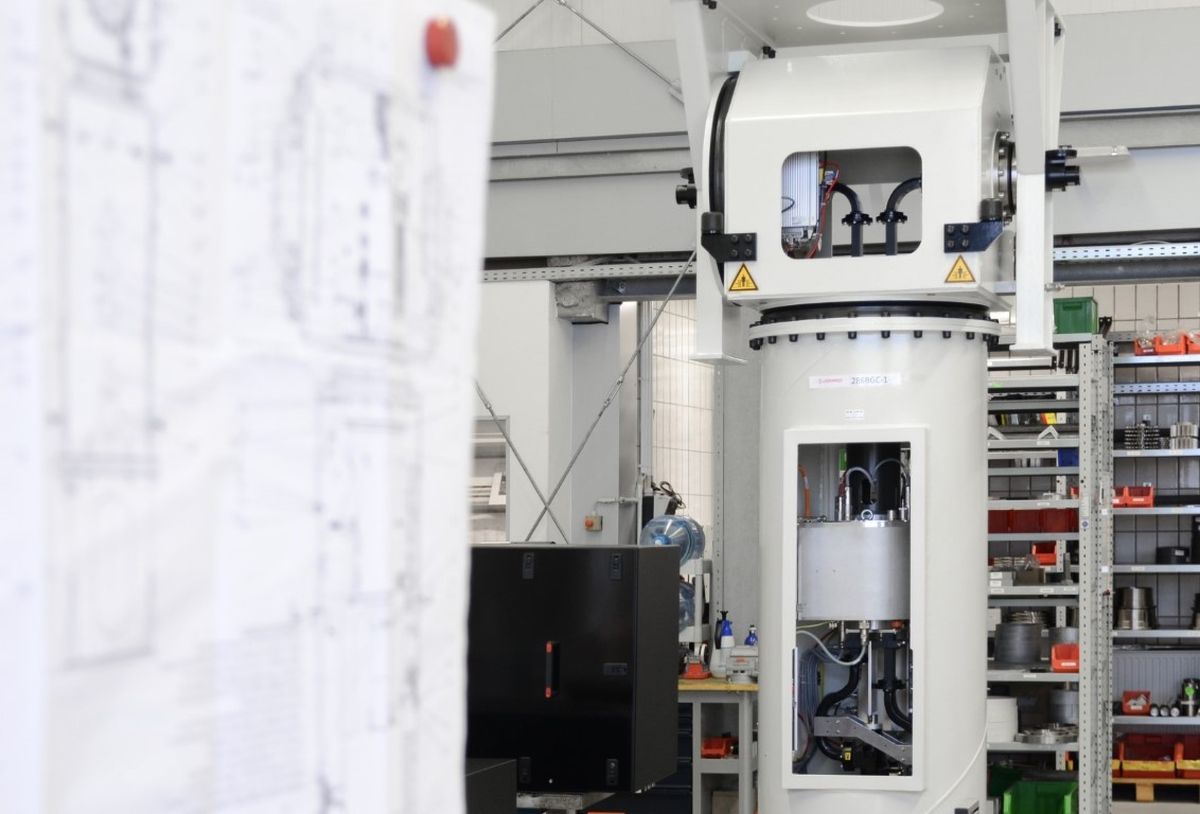

Another requirement for the drive technology was for the servo drives to be installed right next to the motors so that they move along with the application and receive their power supply via sliding contacts. “Our setup is a little out of the ordinary, but with KEBA we were able to find a very good solution”, says Duncker.

Another key factor for Leonardo is their supplier's company size. Duncker adds: “We considered it important to source our products and services from a small to mid-sized business – we made a conscious decision against a ‘big’ business partner. For the big players in industrial automation, we would have been small fry. Now, with KEBA, we get quick response times, fast solutions and uncomplicated access – just the kind of partnership we had in mind.”

"KEBA’s Kemro X system provides us with exactly this type of flexibility – the open platform is a real asset.”

Does climate change dominate industry trends?

While climate change and its consequencesdominate weather events and the media headlines, they do not dominate the trends in the industry. Currently, operators of these systems focus on three areas:

Network Expansion to Prevent Blind Spots: On average, a weather radar system covers an area with a radius of about 300 kilometers. Operators seek for more comprehensive coverage in order to prevent blind spots. This calls for a denser network and the gradual replacement of obsolete systems.

Condition Monitoring to Prevent Outages: It is becoming more and more important to prevent potential outages, or at least to predict reliably when outages could occur. In this context, the condition monitoring capabilities of the systems will play a very important role when it comes to increasing availability.

Faster Positioning and Increased Accuracy: Another growing priority is the faster repositioning of the system between measurements and the improved positioning accuracy.

Our setup is a little out of the ordinary, but with KEBA we were able to find a very good solution.

Accuracy as a Key Factor

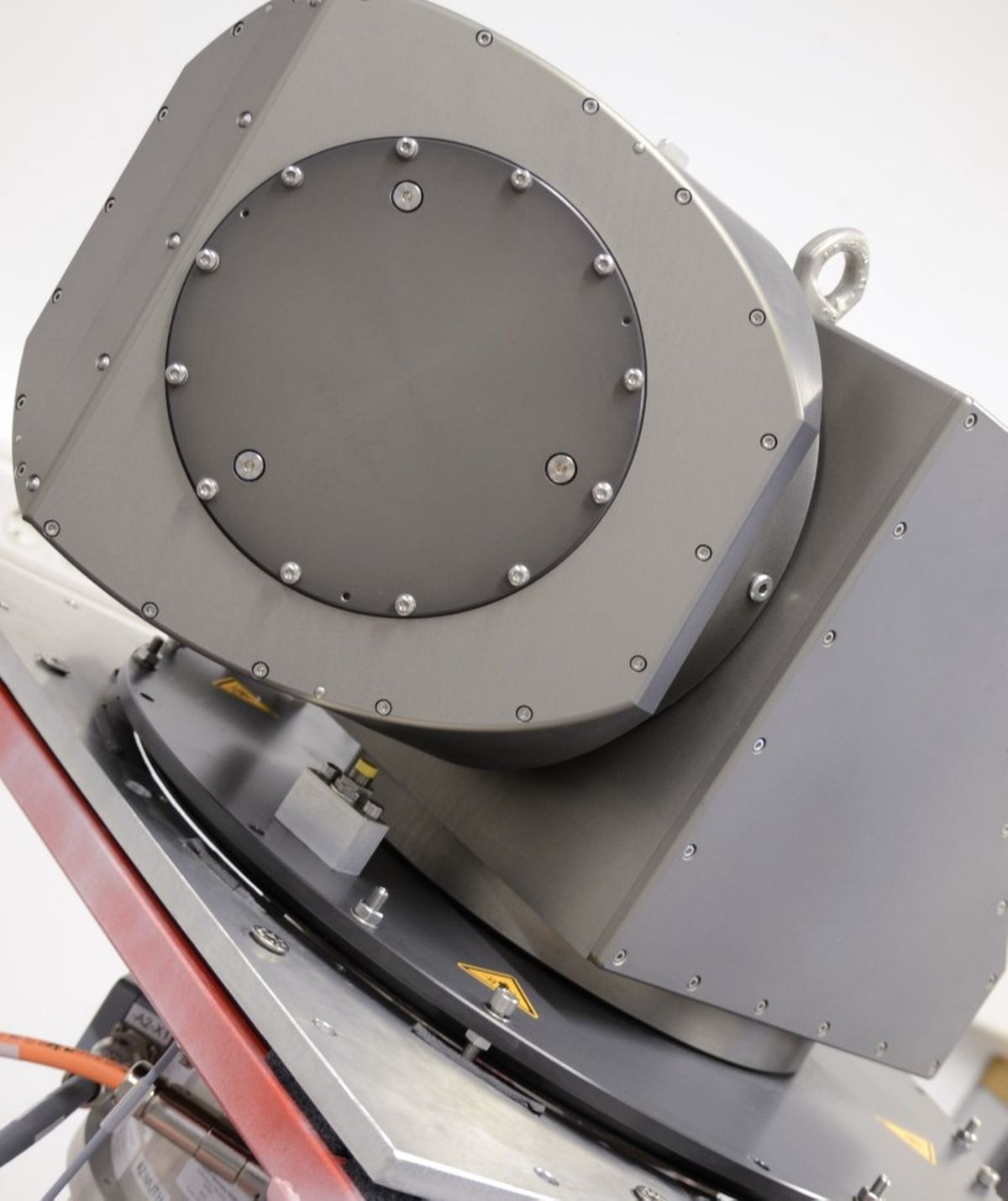

Accuracy plays a vital role overall. For example, more and more airports are looking to use local measurements in order to optimize the safe timing of aircrafts landing and taking off. This is where the lidar system developed by LEONARDO comes in.

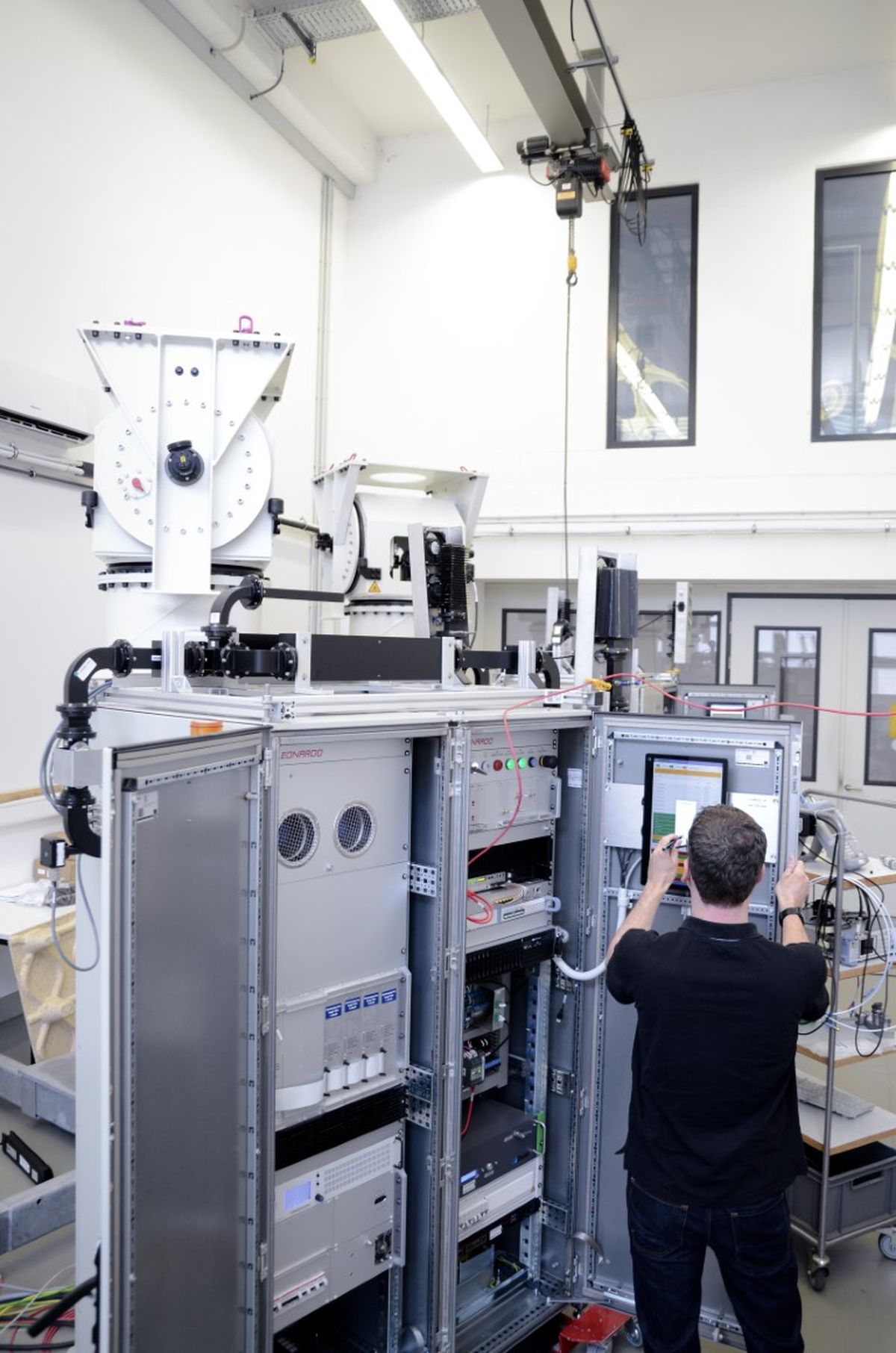

A lidar is a system that emits laser beams which are reflected by particles. The results provide information about the strength of air turbulence and wind shear that can have an effect on the speed which with aircraft can take off and land in succession. Wind shear is a change of the wind speed and/or direction over a short distance. In aeronautics, wind shear and micro gusts at low altitude represent a serious danger for aircraft during take-off and landing. For this reason, lidar systems are continuously scanning the runways. Duncker explains: “The lasers scan the runways both horizontally and vertically. While doing so, one axis rotates continuously while the other one increases its angle continuously, i.e. looks at higher altitudes. This records ‘slices’ of data that are then interpolated into a complete data set.”

In the past, the two axes had to be controlled separately. Thanks to KEBA technology both axes can now be controlled uniformly, achieving a significant improvement of measurement accuracy – and giving LEONARDO a real competitive edge.