KEBA @ SPS 2023

- News

- Events

- 19.10.2023

- Reading Time: {{readingTime}} min

- Share Article

Contents

At the leading trade fair for the industry, the KEBA team will highlight the following topics & products on a stand area of more than 330 m²:

Digitalization

In the area of digitalization, an acupuncture doll is used to ask visitors where industrial companies have their pain points and what digital solutions can be used to eliminate them. "The topic of digitalization is very much about listening to where companies have weak points or hurdles in their workflows and/or processes, or expect them in the future, in order to then jointly consider how digitalization can support them here," says Martin Schwarz, CSO of KEBA Industrial Automation GmbH. The KEBA team will showcase easy-to-integrate solution packages for optimized production and practical tools for efficiency along the automation process.

Artificial intelligence

The Artificial Intelligence Team will use a game to demonstrate how artificial intelligence can be integrated into a control process, for example to recognize and track objects in real time. The team will also present the KEBA AI Development Kit. The DevKit, which is currently in prototype status, consists of a Linux-based KEBA C5 controller including I/O card(s) and the AI extension module. This extension module was developed specifically for AI applications in an industrial environment in compliance with all relevant standards. The toolchain it contains includes all tools for training models for the AI extension module. Furthermore, function blocks are available that allow the models to be executed directly in the PLC code. Industrial companies with AI needs can thus quickly enter the world of neural networks and add the added value of AI to their plants.

Robotics solutions

In terms of robotics solutions, there are several highlights. The drag&bot team (part of the KEBA Group since November 2021) will use a demo to present the simple integration of robotics. The drag&bot module for this is now an integral part of KEBA's Kemro X automation platform.

Another focus in the field of robotics is the official announcement of the cooperation with RoboDK. RoboDK was founded in Canada in 2015 and specializes in offline programming and simulation of robots. Offline programming is the programming of robots outside of the production environment. It aims to eliminate production downtime caused by robot programming on the shop floor.

Simulation and offline programming allow multiple scenarios of a robot work cell to be studied before the production cell is set up. This includes optimal positioning of the robot to minimize cycle times, avoid singularities or ensure reachability. Preparation in the office leads to shorter commissioning times.

The currently available functionality enables the creation of robot programs in the KEBA language KAIRO within the RoboDK environment based on 3D models of parts and systems. An easy way to transfer programs to KeMotion controllers is also available. Robot motion execution can be monitored in a digital environment as well as with the actual robot controller within RoboDK. Other enhancements include workflows for system design and implementation, as well as after-sales support.

Handheld terminals / HMI

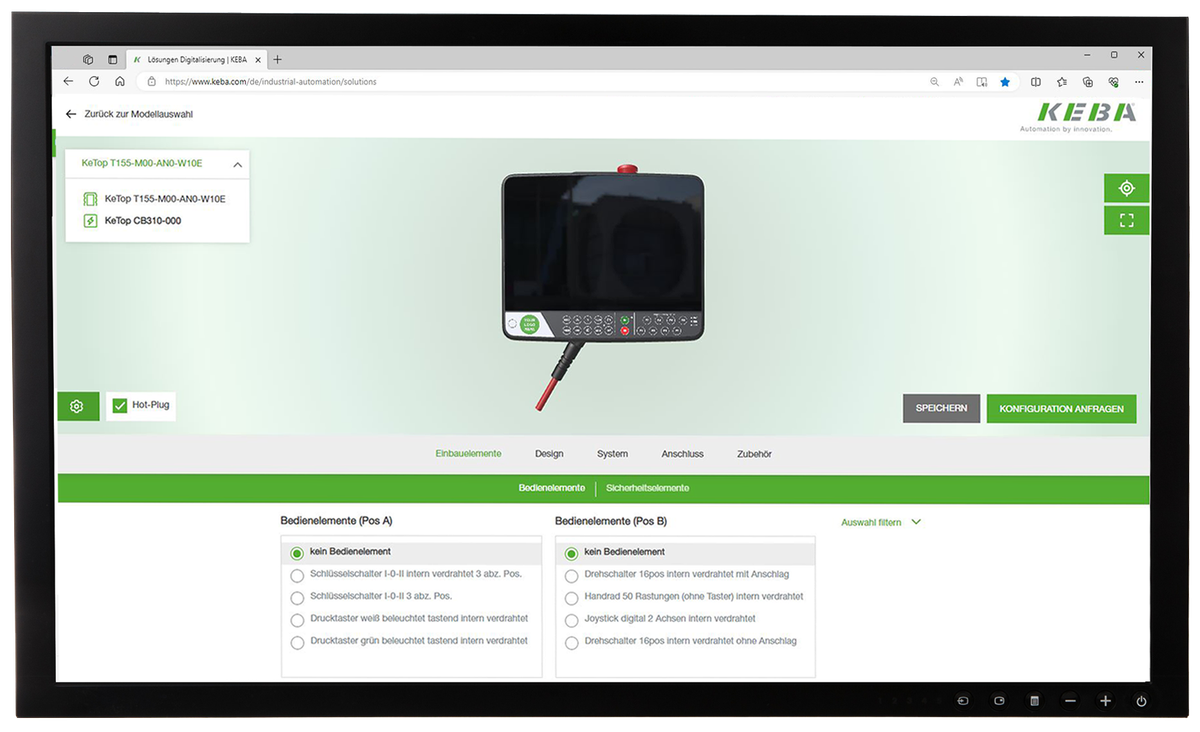

In the area of HMI, the KEBA team will be showing several highlights at the SPS. In addition to Safe-Wireless (our wireless approach) and the adaptive rotary pushbutton "KeWheel", a product configurator will be presented for the first time. In this configurator, users can configure mobile and stationary KeTop panels according to their own needs or requirements with just a few clicks. Users can choose from a large selection of KeTop "Basic" handheld terminals and configure the keypad and the desired design, as well as the mounting elements, in just a few steps. The matching accessories, such as connection boxes and cables, can also be configured.

After the online configuration, visitors can assemble handheld terminals themselves at a dedicated station - all the built-in elements can be plugged together themselves.

By the way: there is a new addition to the mobile KeTop family!

At this year's SPS, we will present our latest addition to the KeTop product family: The mobile handheld KeTop T135!

Drives / Product launch: KEBA KeDrive D3-AC

Modular machine concepts require flexible, compact drive systems. The new KeDrive D3-AC from KEBA is a servo controller that integrates AC mains connection, mains filter and braking resistor as well as three axis controllers in one device. The three-axis servo controller was developed with a focus on three-axis handling kinematics. Cartesian robots in particular often require increased drive power in one of the axes. For this reason, variants with 4 A/4 A/6 A or 8 A/8 A/12 A rated currents are available for the three-axis unit.

If a central control cabinet is used in one solution, the drive technology is integrated directly into each module in the other solution. For the central solution, energy-efficient multi-axis drives with a common DC supply are the first choice. In the modular solution, where usually only a few drives are used, it is important to use compact all-in drives. The new KeDrive D3-AC is such an all-in servo drive, integrating the AC power supply, a line filter and the braking resistor. A special feature is that up to 3 axis controllers have been integrated in one device. This allows a very compact design and extreme reduction of the wiring effort. Single or double axis servo controllers are also part of the portfolio.

KeDrive D3-AC is part of the KeDrive D3 drive family. The KeDrive D3 multi-axis drive system is an economical solution for machines with a larger number of axes. For smaller numbers of axes, KeDrive D3-AC is now an even more cost-effective solution.

Product presentation at the trade show forum:

Titled "Paying less for more flexibility. KeDrive D3-AC", the new KeDrive D3-AC servo controller will be presented to a wider audience by Jörg Brinkemper, Strategic Product Manager Drives and Automation Solutions, on Thursday, 16.11.2023, 13:30 - 13:50 at the Exhibition Forum in Hall 6.

KEBA's other focal points at SPS 2023:

Connectivity, energy efficiency and digitalization – challenges that run through all industries. Some concrete examples at product level:

Digitalization: Solutions for vibration monitoring and sensorless condition monitoring of a complete powertrain - based on the Kemro X platform and applicable to any application.

Energy efficiency: Active supply units, efficient operation of our robotics

Connectivity: Standardization of our interface world with focus on OPC-UA and the corresponding information models with the goal of "Plug & Produce”

Kemro X – the KEBA automation platform for hardware and software

As a complete automation system for hardware and software, Kemro X covers everything a machine manufacturer needs for its smart factory: All mobile and stationary panels, drives and hardware types as well as the engineering tool are built in. The system has a modular structure and the modules can be used like apps on a smartphone. Modules from KEBA, customer-specific or Linux-based standard modules can be used. Linux-based openness allows customers to integrate their own software modules as well as third party software. This allows them to protect their know-how and maintain their independence.

The open system architecture enables the required inter-process communication. Following the principle of a modular system, KEBA has developed an extensive range of software units that the machine manufacturer can use for all automation projects: from engineering tools to simulation tools.