Machine operation under glass as a competitive advantage

- References / Success Stories

- HMI

- News

- 29.6.2023

- Reading Time: {{readingTime}} min

- Share Article

Contents

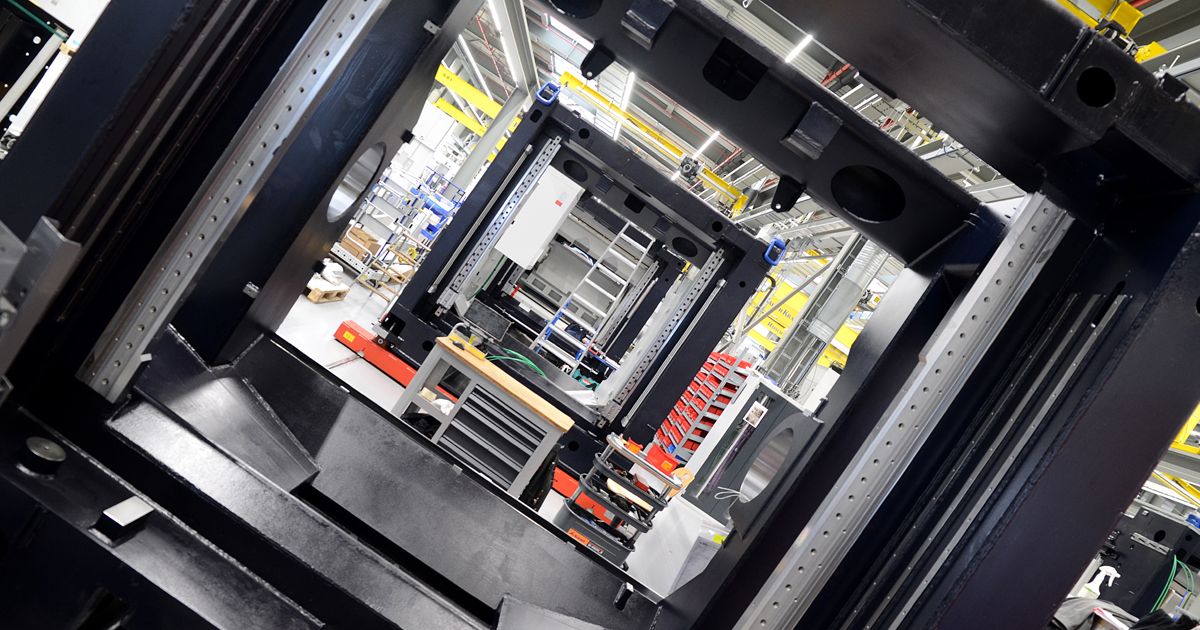

They call themselves “technology people”: because they are passionate about technology, because they constantly question the current state of the art, and because they develop new smart manufacturing solutions on this basis. We’re talking about the approximately 1,400 people who work at SW, based in Schramberg – Waldmössingen, Germany, and who have a love for detail. The importance of the concepts of design and ease of use to this mechanical engineering firm becomes clear on a visit to the bright production halls at its ultramodern location: design – which starts at the reception and continues all the way through to the packaging of the machines.

The product range of SW encompasses multi-spindle CNC machining centers with modular automation, stand-alone manufacturing cells as well as complete manufacturing systems and the associated software solutions.

The machine park at SW includes both single-station machines for the machining of complex, large-volume workpieces and two-station machines for the high-precision machining of sophisticated components. The use of a double-swivel carrier allows the loading and unloading to take place simultaneously to the machining, which ensures minimal non-productive times and higher rates of productivity. The patented mono-block design ensures a considerable degree of machine rigidity for all the SW machines. In addition to ball screw drives, SW also focuses on linear motor drives which find use in the high-performance machining centers worldwide. The acquisition of Bartsch GmbH a few years ago led to the creation of SW Automation – allowing the company to offer complete manufacturing systems.

For SW, the shift, or trend, away from internal combustion engines towards e-motors has been very positive. As the company has very few customers that manufacture combustion engine components only, it is able to cover both areas exceptionally well. The trend towards e-mobility has boosted the business of SW – its biggest new customers are in this segment.

The company generates a large share of its turnover through orders from the automotive industry, focusing on passenger cars, and has been recording annual growth rates of over 20% for several years.

Genuine innovation that sets us apart from the market

“We wanted to break new ground in the field of machine operation, taking account of the fact that we might face resistance from some users. We decided that we were going to make a genuine break: we wanted to bring the entire user interface operations under glass,” explains Peter Siegel, project manager for development, on being asked about the launch of the collaboration with KEBA. This was followed by intensive market research into what was state-of-the-art and which vendors had what technologies in their portfolios or were currently developing them. The existing suppliers weren’t convincing. The bar was very high. Siegel: “With our existing supplier, we wouldn’t have been able to develop anything ourselves, but only to manage the project, i.e., we would only have been able to use the available functionality in their framework, which would have very much limited the usability.” To do this, complex OEM programming would have been necessary, with an unpredictable impact on the control resources. Siegel continues: “Experience with touch applications in dirty areas was also a basic requirement for SW, something that KEBA was able to demonstrate successfully from other projects.”

Moritz Ragg, team leader for user interface development at SW: “KEBA had specific ideas and a superior concept. Our goal: to replicate as much as possible in the software so that we are able to respond to the customer as flexibly as possible and to support them with the user operations – by removing unnecessary content from the respective operational situation in compliance with the standard specifications, for example.”

Convincing: KeWheel and force feedback

The KEBA KeWheel and the force feedback approach proved decisive for the decision. The KEBA KeWheel has a fully adaptive rotary push button as its key operational component. With the KeWheel, overrides, hand wheels, mode selection switches, axis travel buttons and the user interface input options can all be combined in one single device. The KeWheel provides the operator with additional information about the condition of the machine with a wide range of haptic feedback. Siegel: “When we saw the KeWheel, we knew it was exactly what we needed: a genuine unique selling proposition – and one which can’t be found anywhere else on the market with such a degree of functionality.”

The force feedback helped the mechanical engineering firm with the challenge of bringing everything under glass, especially the safety-related challenges. Ragg: “Because our remote service solution also accesses the user interface, and bearing in mind that it is also easier to trigger incorrect user operations with the use of touch-based systems, we required a technical safeguard which only enables axes to be moved in the case of an intentional user action by exceeding a level of force during the actuation, for example.” SW also wanted this function to be replicated “under glass”: hardware solutions such as foot pedals or an additional button weren’t wanted. Ragg: “We were therefore interested in a solution under glass with which we could comply with the standard and enable a single-handed user operation at the same time. Force-feedback-touch was therefore exactly the right technology for us in this area.”

Vertical integration with safety

The team started by developing the hardware together with KEBA and an industrial design engineer. For the conceptualization of the user interface, they worked with a UX designer who had previously completed successful projects with KEBA right from the start – which is how the overall concept for the user interface was developed.

Ragg: “We quickly became aware of the sophisticated level of know-how at KEBA, also in the field of manufacturing. We hadn’t seen in-house developments of this scale or with such flexibility for expansion at any other supplier.” Siegel adds: “The fact that KEBA does everything in-house, from the development and layout to the production, and is also able to implement re-designs quickly and flexibly, had a strong influence on our decision.” Unaware of what the industry has recently experienced in terms of component availability, SW also placed particular emphasis on vertical integration.

The SW team was also strongly influenced by quality-related factors. “At KEBA, we have security when it comes to quality because they do so much themselves,” explains Siegel. “With other suppliers, who get almost all their components and circuit boards from others, there is invariably a considerable degree of dependency on third-party suppliers. At KEBA, we are much faster in the case of a re-design – which is something we have realized far more quickly than we expected. To date, we haven’t experienced any delays in the delivery of components.” When our previous supplier suddenly failed to receive components from China last year, SW was threatened with an inability to deliver due to a lack of panels. Siegel: “Thankfully, KEBA stepped in and delivered 100 panels more than planned for in the forecast, which amounted to approximately 25-30% additional panels.”

Siegel continues: "What we wanted to avoid at all costs was a situation in which there were too many partners – i.e. one that supplies the hardware, another that supplies the software, us doing something else... that was a no-go situation for us. Simply buying the hardware and doing everything in-house wasn’t an option for us either. We didn't have the time or requisite longstanding experience. That was exactly where KEBA offered a good framework.”

Ragg: “The entire workbench for designing the kind of user interface we wanted was ultimately developed and made available by KEBA in-house. Other providers are just the customers of software companies. In the case of a problem this would present the disadvantage that finding a solution could be more difficult – at KEBA, however, we have one contact for all of the technology.”

The difference from other vendors is the direct interaction with the developers

The collaboration: rapid, straightforward and as equals

“Of course, there are ups and downs in every business relationship, and sometimes differences when people aren’t of the same opinion. If I had to describe the collaboration with KEBA Industrial Automation, though, it would be as ‘very dynamic’,” emphasizes Ragg. “There are often challenges during the development process that nobody could have predicted before. Whenever problems like this are discussed with KEBA, however, it is always possible to find a solution very quickly. At other providers, a lot of time and work can pass before you talk to decision-makers about new approaches. When it comes to the implementation, it sometimes takes even longer... At KEBA, we don’t have to go through anything like that.” Siegel adds: “In the case of changes in the development environment, we can organize a change request very rapidly. This means that the functionalities are already implemented in the final version.”

Another thing that they both noted during their collaboration with KEBA has been the short and direct channels of communication and the agile nature of their approach. Siegel: “The developers arrange things quickly between themselves. You can approach them with your questions, concerns and suggestions directly and will always find an open door. That is certainly one of the points that allowed the project to progress so quickly. You deal directly with the people who are driving the project and participating in its implementation. There are no intermediaries.”

“The difference from other vendors is the direct interaction with the developers,” explains Ragg. “I recently sat down and met with the KEBA developers in person, which is something I’ve never done before in this kind of a project.” The fact that this type of collaboration deserves to be called ‘agile’ is also reflected in the dynamics: there were only six months between the first “stroke of the pencil on the drawing board” and the presentation of the prototype version of the user interface.

Another thing that contributes to the dynamics is the fact that KEBA Industrial Automation doesn’t deliver a standard “off the shelf” solution, but develops approaches that are tailored to the respective customer. Siegel: “During the project, KEBA focused on our application and, as is the case with other automation providers, they don’t have to start by testing it against their system and all their other previous applications when they make changes, because every change has to match their full scope of services and can’t be different from the ones that already exist. It is those kind of things that make development processes much slower.”

“KEBA is far more than just an HMI specialist.”

“Through the acquisition of LTI a few years ago, KEBA Industrial Automation has developed and positioned itself much more strongly in the direction of mechanical engineering,” explains Siegel. SW can also see potential for further collaboration beyond the area of HMI. Siegel continues: "The 6D spindle has caught our attention, for example, which could be of interest to us for operations that have low machining forces.” The mechanical engineer also considers the development of concepts for remote maintenance to present an exciting challenge for a possible joint future. The approach of drag and bot GmbH, a company acquired by KEBA more than a year ago that specializes in the integration of robots, could also be an area of collaboration.