How Europoliuretani got enabled to flexibly use 6-axis anthropomorphic robots as CNC machines.

- News

- References / Success Stories

- Automation

- Drive Technology

- 2.11.2023

- Reading Time: {{readingTime}} min

- Share Article

Contents

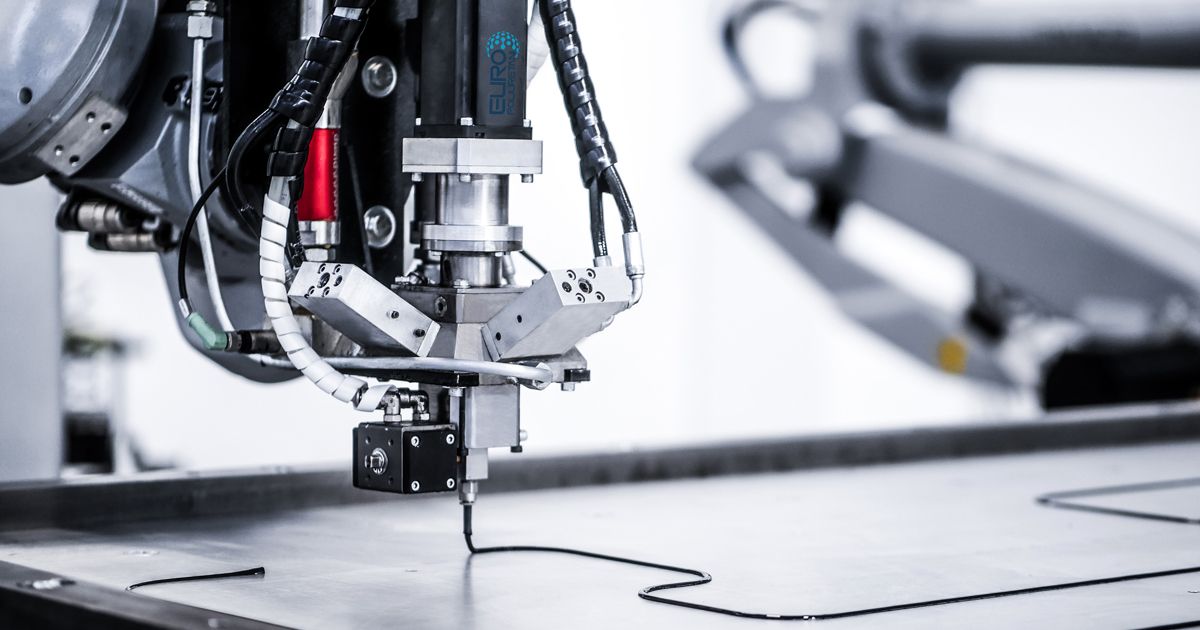

EUREKA SYSTEM's profound knowledge in software development, combined with KEBA's cutting-edge automation solutions, has resulted in the creation of approaches capable to transform and optimize more than one production process. A good example is the robotic solution from EUREKA SYSTEM, called CAM-ROBOT, developed for Europoliuretani, using KEBA’s motion and robotics libraries.

Europoliuretani is an Italian company, located in the comune of Padua, that designs, produces and sells foaming and gasketing machines as well as adhesive dispensers.

The team of Europoliuretani relied on EUREKA SYSTEM to develop a solution for their robotic system to mix, dispense, and apply polyurethane foam for customized gaskets. Eros Contò, CEO of EUREKA SYSTEM: “The goal was a robotic solution that allows Comau 6-axis anthropomorphic robots to be used as CNC machines applying polyurethane gaskets using dispensing paths that are dynamically defined at the same time the order is processed – a true challenge on multiple levels”. Since the parts on which the gasket is to be applied are personalized (batch size is 1), and thus differ from batch to batch, the robot must be able to follow each time a complex and unknown trajectory.

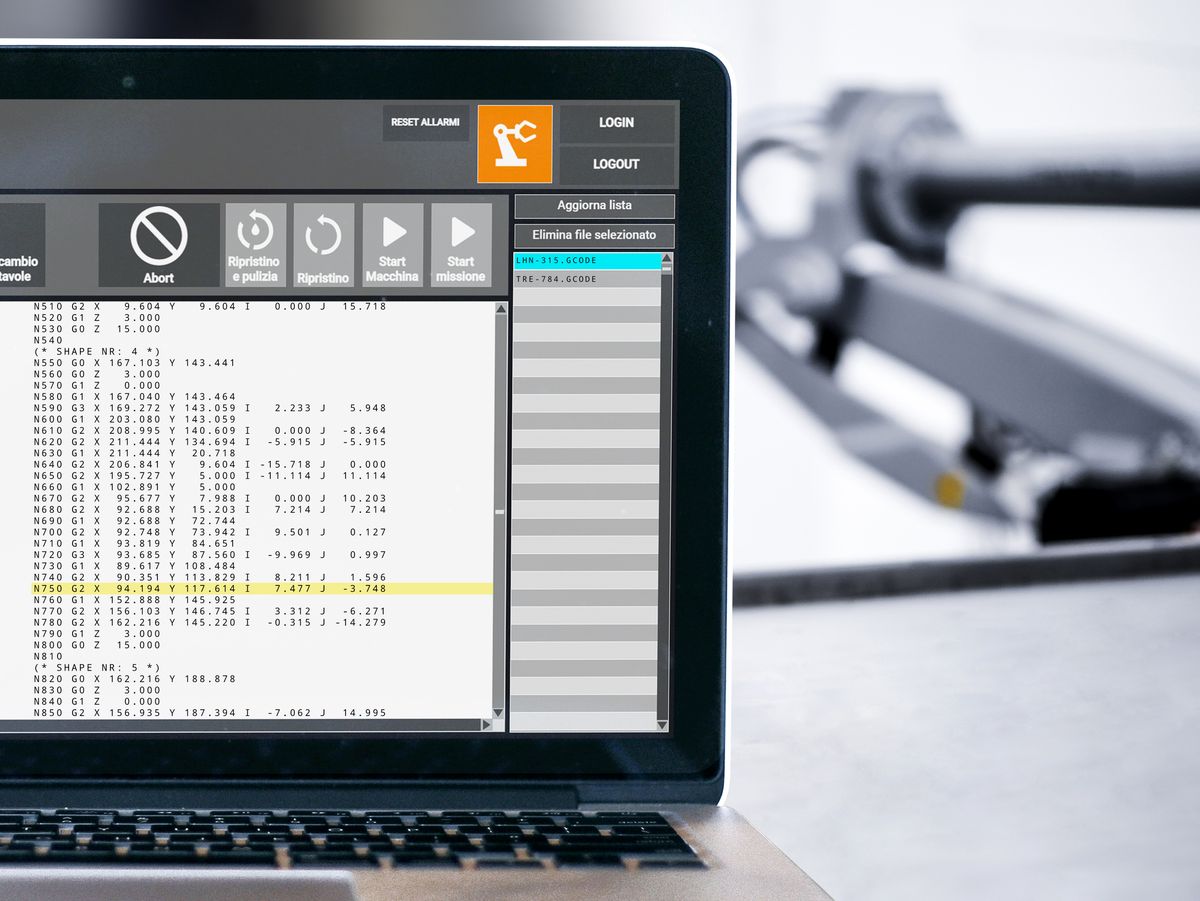

To carry out CNC machining with an anthropomorphic robot using dynamic toolpaths, EUREKA SYSTEM interfaced it with G-code interpretation software (the language applied by CNC machines according to DIN 66025 standards). Time after time, the software generates the high-precision toolpaths to be followed by the robot to machine the parts of that batch along fixed-angle 3D paths. This conversion is executed on the fly, using a user-friendly interface directly manageable by the operator on the shop floor.

The steps to process robotic paths:

- importing any customized CAD-designed machining path;

- transforming the .DXF file into a toolpath

- managing specific parameters (tool start/stop, etc.);

- automatically generating the corresponding robot program from the G-code.

Thanks to the CAM-Robot solution, setup times between one workpiece and the next have been reduced to zero: it is no longer necessary to write the robotic paths manually or to pre-set and set up a CNC machine to perform the machining. Using CAM-Robot, the operator can simply import the .DXF file for the part ready to be sent for machining, and in a few steps the robot will execute the new dispensing path for the gasket.

The role of KEBA Industrial Automation: enabling complex automation processes

A KEBA controller manages the motion and safety controls and the logic programming of all the different tasks, hence making this complex automated process possible at all. The solution offered by KEBA consisted of a Codesys controller integrated with a comprehensive suite of software libraries. This combination was further complemented by KEBA’s motion hardware, Kemro X, consisting of servo drives and motors known for their exceptional reliability and ease of use. “The reason to cooperate with KEBA was not only the reliability and ease of use of their solutions”, explains Eros Contò, CEO of EUREKA SYSTEM. “Only with the KEBA solution we have been able to efficiently manage the 6-axis robots in the application for Europoliuretani because the Comau robotic kinematics are integral part of the KEBA library. We thus talk about a much deeper integration into robotics by KEBA compared to all other suppliers”.

As a system integrator, we can only afford truly reliable partners,” says Valentina Passarella, responsible for Marketing with EUREKA SYSTEM. “In case of KEBA this goes on the one hand for their solution offered – and I mean herewith the comprehensive capabilities of the KEBA system, which encompassed motion control, safety features, and servo controls specifically tailored for robotics.” she adds. The KEBA controllers offered the necessary functionalities to effectively handle the complex tasks required by the robots, ensuring precise and reliable performance. “It is not only about reliable solutions, though”, continues Passerella. The cooperation between EUREKA SYSTEM and KEBA is a technical partnership characterized by a deep understanding of the importance of professional assistance throughout the development and commissioning stages. Passarella: “Both companies recognize that the quality of a system, encompassing both hardware and software, cannot be fully appreciated without the support and expertise provided to the integrator during these critical phases. By prioritizing technical assistance, EUREKA SYSTEM and KEBA demonstrate their commitment to ensuring that the implementation and integration of their solutions are seamless and efficient.” This collaborative approach facilitates effective problem-solving, timely support, and a smooth transition from development to operational deployment. “As EUREKA SYSTEM specializes in the development of special robotics solutions, both the possibility and probability of integrating KEBA technologies in future projects are constantly rising,” states Contò.