Partnership between RoboDK and KEBA

- News

- Robotics

- 20.6.2024

- Reading Time: {{readingTime}} min

- Share Article

Contents

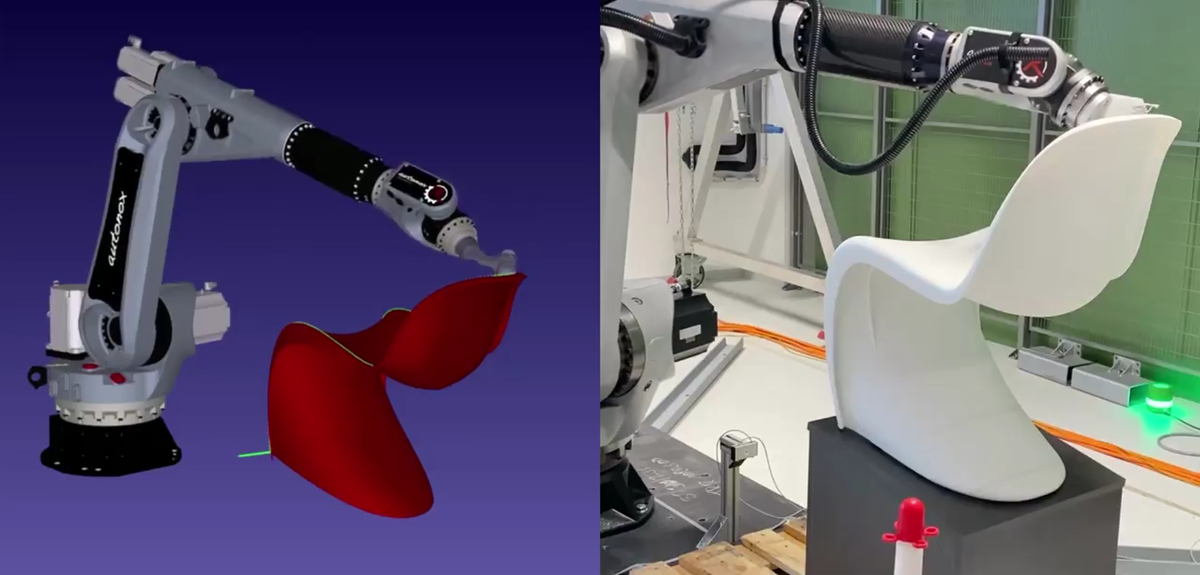

The two open platforms make it possible to create and test multiple robot cell scenarios from the desktop and only then build the real production cell.

Together, we enable the entire life cycle of a process solution with integrated robotics, from the preparation of the offer to implementation and after-sales support.

Succesful integration

Michael Garstenauer, Product Manager Robotics at KEBA Industrial Automation: "RoboDK developed a KeMotion KEBA driver for the successful connection of our control technology, which is based on our new secure and powerful web APIs and thus enables corresponding workflows. This also benefits our existing customers, who are already supported by the RoboDK robotics library."

Benefit from two open platforms

OEM developers can now combine the advantages of Kemro X and RoboDK. The two open platforms make it possible to create and test several robot cell scenarios from the desktop and only then set up the real production cell. This means that the optimum positioning of the robot can be determined before it is actually used. Cycle times are minimized, singularities are avoided and accessibility is ensured. This leads to shorter commissioning times, conserves employee resources and ultimately allows reliable quotations to be prepared quickly for customers. Garstenauer says: "If, for example, you program a robot to paint a complex 3D structure such as a designer chair, this can often take hours - with RoboDK you can do this in just a few minutes."

Simple transfer to KEBA control unit

The currently available functionality enables the creation of robot programs in the KEBA language KAIRO within the RoboDK environment based on 3D models of parts and systems. A simple option for transferring to KEBA controllers is also available. The execution of the robot movement can be monitored both in a digital environment and with the actual robot controller within RoboDK.

Advanced simulation and programming function

Samuel Bertrand, Software Development Lead at RoboDK, says: "The integration between Kemro X and RoboDK provides KEBA users with advanced simulation and programming capabilities, including CAD to path features, offline programming (OLP), digital twin capabilities, collision checking, CAM for robots, and more. By integrating KEBA systems into RoboDK, we aim to enhance efficiency, control, and flexibility in robotic automation. "

Easy maintenance thanks to digital twin

Even after the production cell is set up and running, it can be easily maintained or modified using the digital twin. The recorded data makes it easy to quickly identify problems and provide efficient customer support and service. The collaboration between KEBA and RoboDK is also of great benefit to end users: It minimizes downtime during product changes and by quickly identifying problems, it guarantees them effective service & support.

OEM developers can now combine the advantages of Kemro X and RoboDK.

The most important advantages of cooperation:

Advanced Simulation: Allows users to virtually create and test robot cell scenarios in a simulated environment to ensure optimal positioning and performance prior to real-world implementation.

Reduced set-up times: Minimizes commissioning times and conserves employee resources by simplifying programming tasks and set-up procedures. The main feature is the automatic generation of robot paths for new parts or products to be processed by the robot system. Hours of manual teach-in on the robot are replaced by fast and simple software-controlled processes.

Improved monitoring and maintenance: Facilitates monitoring and maintenance through digital twins that ensure quick identification and resolution of problems.

Reliable and efficient support: Guarantees effective customer service with minimal downtime for product changes and fast problem-solving options.